Fill out the feedback form for a consultation

Clean rooms complex

Medical Innovative Technologies

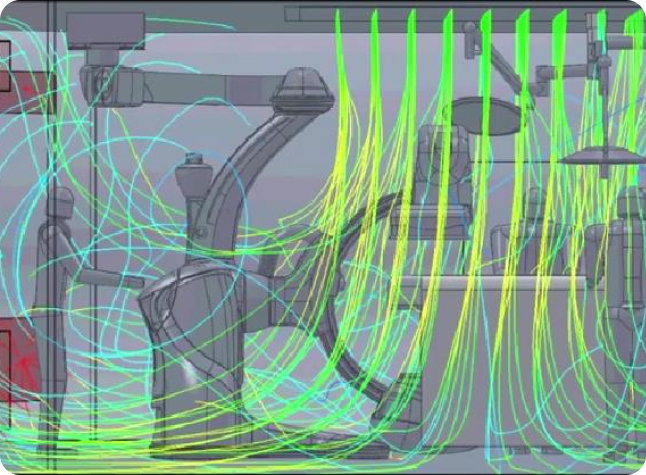

The Cleanroom Complex (CRC) is an enclosed space with air exchange systems that keep the air clean. The sterility of operating rooms and other hospital premises largely determines the success of surgical interventions, the quality of performed examinations, patient recovery and rehabilitation.

The objective of clean rooms is to disinfect the air by minimizing the entry, generation and accumulation of biological, chemical and other particles within the room.

Main requirements to the enclosing structures of clean rooms - tightness and protection of the working area of the clean rooms from building structures and external factors.

What we offer

We offer a technological solution for creation of a "clean rooms complex" for the following premises of medical facilities, which are subject to increased requirements to the air environment quality:

- operating units;

- intensive care units;

- maternity departments;

- aseptic boxes for patients with immunodeficiency conditions;

- hemodialysis rooms;

- central sterilization departments;

- blood transfusion departments (station);

- sectional rooms;

The clean rooms complex is a complex and capital-intensive engineering solution that requires a professional and integrated approach.

Our Advantages

- Careful and high-quality performance of all stages of work, starting with project analysis and medical and technological design, ending with the facility commissioning;

- Use of only high-quality materials in work;

- Partnership with the world leaders in manufacturing and equipment of the clean room complex;

- Wide choice of enclosing structures in accordance with the customers’ wishes, equipment manufacturers requirements and design solutions;

- Extensive work experience;

- Compliance of the solutions with all requirements for clean pharmaceutical rooms regulated by international, national, industry standards and GMP rules (Good Manufacturing Practice).

Our team

Licenses / Certificates

About us

18+

Working experience

60+

Turnkey” projects

70+

Implemented Projects

Work Stages

1

Audit and consulting of the project;

2

Medical and technological design;

3

Construction of engineering networks on a turnkey basis;

4

Creation of air preparation systems, power supply /lighting, automation, heat supply and refrigeration systems on a turnkey basis;

5

Construction of enclosing structures;

6

Installation and commissioning of CRC and technological equipment;

7

Warranty and post-warranty maintenance.